Containers do not have many moving parts, but they do have more parts than you might think. There are five basic parts to a container: the walls, the roof, the corner posts, the doors and the floor.

The walls. Container walls are made of corten steel. The steel is about 14 gauge and the walls are corrugated. The walls connect into a top rail where the wall and roof meet and a bottom rail in the floor. They meet up at the corner posts.

The roof. Container roofs are also corrugated, but that corrugation tapers off so that rain and melting snow drain to the sides and then to the corners of the container. They are also made of 14 gauge corten steel.

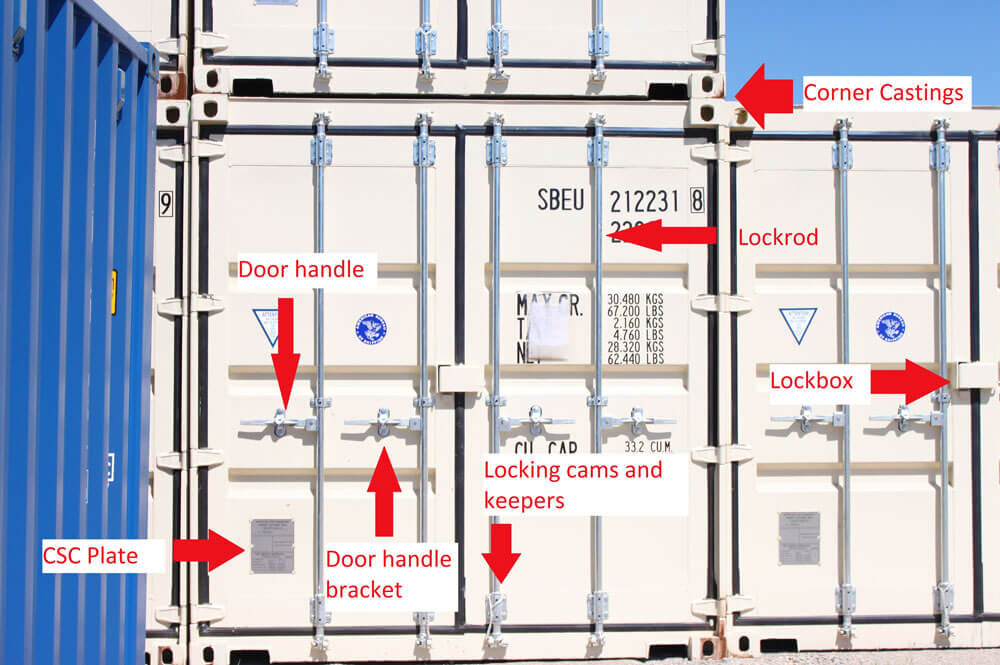

The corner posts. The four corner posts of the container hold all the weight when stacking containers. Containers sit corner post to corner post, not the floor sitting on the roof of the container below it. The corner posts by the doors are smaller than the ones in the nose (non-door end) of the container. They have corner castings on them so containers can be locked into each other on ships.

The doors. Containers and two doors that swing open on one short end of the container. They have different corrugation than the rest of the container. They are closed by lockrods that run the height of the door. The lockrods have locking cams at the top and bottom of them that hook into keepers that are welding above the header and below the threshold of the container. You use door handle levers to turn the lockrods to open and close the doors. The levers are held close to the door by door handle brackets. The brackets have a place to put a padlock to lock the handle against the container door. One-trip containers will also have a lockbox, which is a metal box that is welded to the right door and extends over the left door. There is a post welded to the left door that fits into the box when the doors are closed. You slip your padlock onto the post and the box protects it from being cut off. Check out this video on how to open and close a door.

The floor. Container floors are made of steel and plywood. Steel cross-members span the width of the container. A bottom rail runs around the perimeter of the cross-members. Three-quarter inch marine-grade plywood is screwed into the cross-members to create the floor. Then the whole floor is coated on the underside with a sealant that has pesticides in it. 40' containers have a steel plate in the nose (non-door end) in the middle to give the floor extra protection from the trailers and chassis that move them around.

Maintenance and repair. Caring for your container does not need to be too time consuming. Inspect your container regularly and address problems early. If you see an issue forming, take care of it right away from managing rust to any floor issues. You can extend the life of your container by putting additional protection on the roof. This can be roofing tar or other materials.

.jpg)

.jpg)